Concrete Dust Interceptors are Mandatory

In the world of concrete polishing bidding is extremely competitive and the margins are tight. It is imperative therefore that one have reliable and efficient equipment to ensure the job is completed on time and on budget. The last thing any contractor needs is a schedule delay due to equipment maintenance, such as frequent operator intervention to clean clogged filters, or, even worse, catastrophic equipment failure such as a vacuum motor burnout . This not only shuts down the job but incurs the contractor with highly expensive replacement costs. Profits poof! For these reasons and more dust interceptors are mandatory for large concrete grinding and polishing jobs.

You Need to See Your Work

Many contractors are moving to a dry grinding method1 as opposed to wet grinding which leaves the floor coated in a slurry. If the floor is covered in slurry the operator cannot see the actual grind patterns on the surface and thus doesn’t know if he is proceeding too fast, too slow, or moving unevenly. While there is no such thing as “dust-free” grinding, numerous patches of dust on the floor are a good indication that there is not enough suction from the vacuum. The operator must stop work, backwash or pulse the filters, and then dump the tank before resuming operation.

You Need Suction

The key to powerful suction is the lift of the vacuum motor and the surface to air ratio of the filters. Pleated PTFE (Polytetrafluoroethylene a.k.a Teflon) coated filters have a much greater surface area than bags, last dramatically longer than bags, keep all but the the smallest submicron particles on the surface of the filter, and maintain high CFM while keeping pressure drops to a minimum and eliminating filter blinding. The result is consistent and reliable performance without suction drop.

You Need Speed

Time is money. If you are a typical contractor then you probably only like to stop only for breaks and lunch. If work stops for cleaning, maintenance or any other reason impeding production you’re generally not happy about it. With a dust interceptor, at least 85% of the dust is captured before reaching the vacuum or the filters. So you go from short cleaning cycles to long cleaning cycles and your skilled operators can stay on task rather than stopping the machine to go beat filters. As an added benefit, the life of the PTFE filters and valves is extended, and the HEPA filter stay surprisingly clean.

How it Works

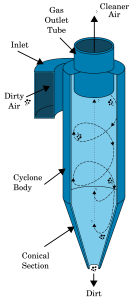

Cyclonic dust collectors have been around since World War II and the design hasn’t changed much since then. The physics of separation is simple and effective (they are also called pre-separators) and is based on centrifugal force. A collector use cyclonic action to separate dust particles from the incoming dirty air stream. In a typical cyclone, the dust gas stream enters at an angle and is spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, these particles fall either into a hopper, drum, or bag located underneath.

Cyclonic dust collectors have been around since World War II and the design hasn’t changed much since then. The physics of separation is simple and effective (they are also called pre-separators) and is based on centrifugal force. A collector use cyclonic action to separate dust particles from the incoming dirty air stream. In a typical cyclone, the dust gas stream enters at an angle and is spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the wall of the cyclone. After striking the wall, these particles fall either into a hopper, drum, or bag located underneath.

The most common types of centrifugal, or inertial, collectors in use today for concrete dust collection are single-cyclone separators. They create a dual vortex to separate coarse dust from fine dust. The main vortex spirals downward and carries most of the coarser dust particles towards the cone. When the airstream can no longer go any farther down the cone it reverse direction. The inner vortex, created near the bottom of the cyclone, spirals upward and carries finer dust particles and cleaner air to the final extractor.

Cyclonic dust collectors are purpose-built for the type of dust they will be collecting. And although they have no moving parts the engineering is critical to success. A cone that is too long will not allow the dust to drop. A cone that is too short will suck the collected dust right out again. A collector designed for concrete dust will not work well, if at all, for wood dust, and vice versa. The best-of-breed cyclones, used in factories and on large commercial projects, are custom-engineered to work in tandem with extractor vacuums having very precise airflow and water lift specifications. To operate effectively it is always best to procure equipment from the same manufacturer.

The Perfect Trifecta

Concrete Polishing Solutions (CPS) G-320 Grinder (left), combined with the Cat-5 Extractor Vacuum (middle) and Cat-5 Dust Interceptor (right). This industrial-grade, equipment trifecta dramatically increases performance and cost savings. The Cat-5 Extractor features a 20 hp, 400 CFM vacuum with 120″ of water lift that maintains suction in the toughest conditions. Both Cat-5 units feature a Longopac continuous bagging system: a cost-effective, disposable bagging system providing minimal downtime, easy clean-up and a safe working environment. All units feature heavy-duty welded frame construction with powder coated finish designed to withstand the toughest jobsite conditions and provide years of reliable service.

Notes:

- Warning: Grinding and polishing dry concrete releases dangerous silica dust into the air. Refer to OSHA regulations for proper procedures to protect exposed workers and decontaminate clothing and equipment.

Follow Us